Veneer Board

Timber veneer is an ideal way to get the natural beauty of timber with the workability of MDF or particle board. Decorative timber veneers are perfect for indoor use and once glued to a substrate are less prone to warping or splitting as natural timber is.

Our timber veneer is sliced 0.6mm thick and pressed on to a substrate to create flat sheets. Depending on the way that the timber is cut and laid out, the natural growth rings will show a variety of grain patterns and features. Our in store range of timber veneers are pressed on to either MR MDF or HMR particle board. Our stock veneer species are Tasmanian Oak, American Oak, Blackwood, Pine and Black Butt Feature Grade (NFG).

Whether you need a couple of sheets, or enough for a large joinery project, timber veneer can be pressed onto many different substrates such as Black core MDF, Fire retardant MDF, and plywood, and we have access to almost any timber species available.

DON’T FORGET – we specialize in cutting, edging and routing these boards for cabinetry and furniture components. We can also perforate veneered panels to improve the acoustics for halls, auditoriums and large public spaces.

- Superior Stability when compared to timber

- Versatile substrates for various requirements

- Matching edging and various sheets sizes available

| Thickness | Sheet size | Tasmanian Oak or Vic Ash | American Oak – Crown cut | Radiata Pine | Black Butt – Feature grade | Blackwood |

|---|---|---|---|---|---|---|

| 2.2 mm | 2400 x 1200 | ✔ | ✔ | ✔ | ||

| 5 mm | 2400 x 1200 | ✔ | ✔ | ✔ | ✔ | ✔ |

| 10 mm | 2400 x 1200 | ✔ | ||||

| 12 mm | 2400 x 1200 | ✔ | ✔ | ✔ | ||

| 17 mm | 2400 x 1200 | ✔ | ✔ | ✔ | ||

| 19 mm | 2400 x 1200 | ✔ | ✔ | ✔ | ✔ | |

| 2700 x 1200 | ✔ | ✔ | ✔ | |||

| 3000 x 1200 | ✔ | ✔ | ✔ | |||

| 3600 x 1200 | ✔ | ✔ | ||||

| 25 mm | 2400 x 1200 | ✔ | ✔ | |||

| 32 mm | 2400 x 1200 | ✔ | ✔ |

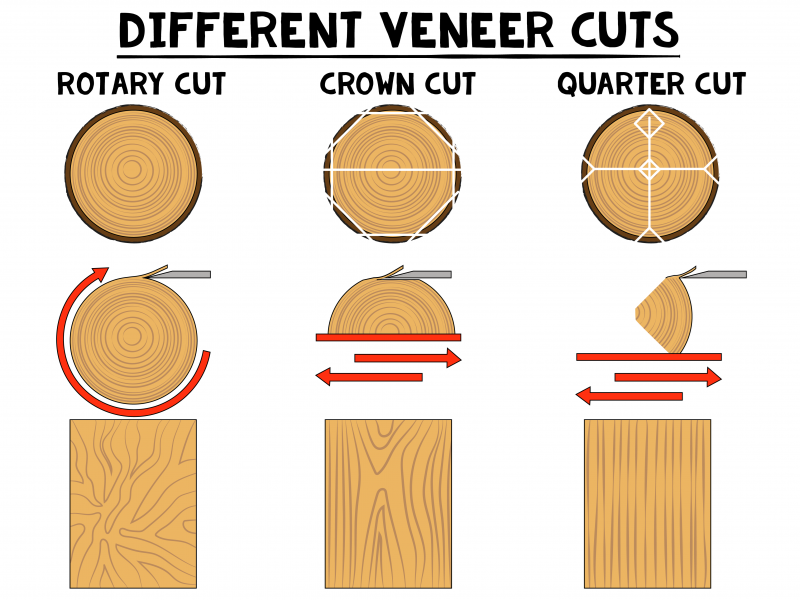

Rotary Cut

Veneer is created by slicing the log around its circumference – much like sharpening a pencil. This cut is mostly used in plywood production.

Crown Cut

For crown cut veneers, the log is cut in half, and the halved log is then sliced straight across. Crown cut veneers tend to have a strong grain pattern in their center and a more linear effect at the edges.

Quarter Cut

To create a quarter cut veneer, the log is first cut into quarters, creating four flitches. Each quarter flitch is then straight sliced, at roughly right angles to the growth rings. This then produces a veneer with a uniform lined vertical grain.